It is important to understand the construction and operation of the circuit breaker as they are used in nearly every installation from domestic buildings to high voltage electrical utility substations. They are heavily relied upon to protect our electrical systems when abnormal circumstances arise. With varying shapes, styles, and sizes it is important to understand the correct methods for maintaining this equipment to ensure the safety of people and your assets is not at risk.

The main type of circuit breakers in low voltage installations are:

MCCB’s are generally smaller in size and have a lower current rating. These circuit breakers are always fixed circuit breakers installed into an electrical switchboard. They consist of the circuit breaker frame, the operating mechanism, an interrupting structure (arc suppression), a trip unit, and terminal connections which connect the MCCB to the circuit’s conductor. Some simpler versions of breakers rely on a thermal magnetic strip for protection whereas others can be adjusted and set via solid state or digital trip units and have much higher interruption ratings.

ACB’s on the contrary can be quite large and have a much higher current rating. These circuit breakers are usually utilized in heavy industrial situations where large equipment with high load demands such as motors, furnaces etc. are present. These circuit breakers can be of fixed or withdrawable nature and are generally fitted with solid state or digital trip units.

When performing maintenance in shutdown situations it is imperative to check the components of the circuit breaker for general wear and tear and ensure all electrical components are sound by utilizing electrical tests to verify contacts etc.

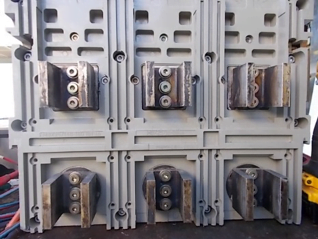

The circuit breaker has two main types of disconnects. The main disconnects which connect the main circuit breaker to the bus section of the switchboard and the secondary disconnects which connect the control circuits of the circuit breaker. Visual inspections for any loose connections and low resistance testing verifies the condition of these connections. If any loose connections are found, they are required to be re-torqued to manufacturer specifications. Earthing disconnects can also be found which connects the circuit breaker frame to earth and allows the protection device to operate as quickly as possible in fault conditions.

The circuit breaker also has three main types of contacts. Arcing contacts, main contacts, and auxiliary contacts. The arcing contacts are generally constructed of a hardened material such as silver, tungsten, cadmium or zinc which ensures they will not deteriorate as quickly. The arcing contacts make contact first which draws the arc across them preventing the main contacts from drawing the arc which preserves their lifespan. The main contacts of the circuit breaker are generally larger and constructed of a softer more conductive material such as silver. This ensures a low resistance path for high currents to flow. The auxiliary contacts are what connects the control circuits of the circuit breaker. These can provide functions for automatic operation such as operation of motor mechanisms, sending open and close signals to the circuit breaker remotely or monitoring the status of the installation. It is important to inspect these parts for damage and perform electrical tests such as low resistance testing and insulation resistance testing to verify safe operation of the circuit breaker.

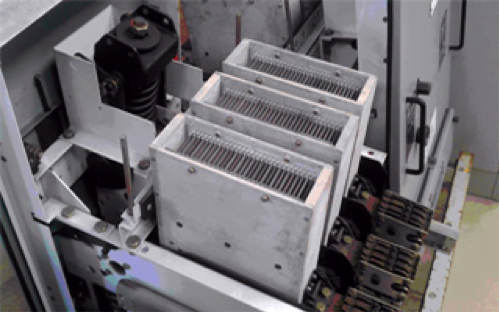

The arc chutes are utilized in the circuit breaker to contain the arc when opening and closing the circuit breaker. It is designed to stretch, cool, and deionize the arc which dissipates into the arc chutes very quickly. They are generally installed right above the arcing and main contacts to draw the arc up and away from the operating parts of the circuit breaker. It is important to inspect and clean the built-up carbon off these chutes during maintenance.

The operating mechanism of the circuit breaker is all mechanical and servicing and lubricating of parts is essential. The operating mechanism is often referred to as stored energy as a spring is mechanically charged to ensure the mechanism is a ‘quick make’ and ‘quick break’. This ensures the smallest possible arc is drawn during opening and closing of the contacts. It is particularly important when cleaning and inspecting these parts during maintenance that the springs are fully discharged. This ensures the contacts are unable to be operated while putting your hands inside to clean the contacts.

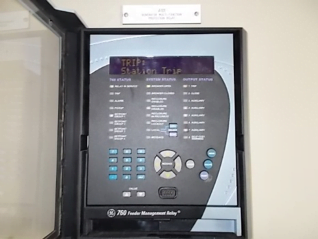

These devices are extremely important for the protection of the electrical circuit. Most modern circuit breakers have digital trip units and the functions are long-time delay (LTD), short-time delay (STD), instantaneous (INST), and ground fault (GF). It is important to verify the protection device is operating within the manufacturers specified limits. This can be achieved by either primary injection (through the main contacts of the circuit breaker) or secondary injection (through the auxiliary contacts from the current transformers). Trip times of the circuit breaker is recorded which verifies the protection is within the manufacturers tolerance limits.

It is imperative to ensure the circuit breakers of your electrical installation are operating correctly for the safety of persons and the safety of your electrical equipment. The consequences of poor electrical maintenance of these devices results in fire, loss of supply, damage to equipment and persons, and loss of business operations.

Eccentricity recommends a proactive approach to maintenance by scheduling regular energized and de-energized testing into your maintenance protocol. Give us a ring today to see if we can help you manage your electrical assets.